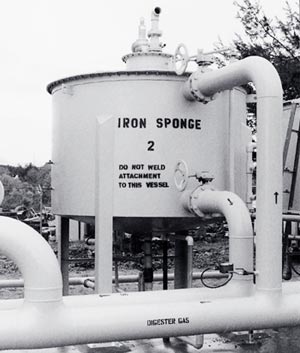

SULFIDE REMOVAL PROCESS

Time-proven, the "Iron Sponge gas sweetening process" has been "sweetening sour gas" in sulfur-bearing gas fields for over fifty years. This is the most

effective method of removing hydrogen sulfide from a gas stream. Digester gas passes through the permeable bed containing hydrated ferric oxide. Hydrogen

sulfide reacts with ferric oxide, as demonstrated by the

following equation, forming water and black, solid, ferric sulfide.

A Marcab Gas Purifier will remove all hydrogen sulfide present in gas passed

through the vessel. Marcab systems are

passive; requiring no operator nor any mechanical or electrical power.

|

|

MARCAB'S REGENERATION METHOD

Marcab's method of regeneration (U.S. Patent # 4,849,191) requires in-vessel flooding of the media, with water, and subsequent

introduction of air bubbled through the flooded bed. The bubbled air starts the reaction of

oxygen with the ferric sulfide while the heat of the exothermic reaction is harmlessly absorbed by the water.

After 24 hours of aqueous regeneration, the bed is drained. Airflow continues while water vapor dispels any lingering warmth. Within

24 hours the temperature of the escaping vapor reaches ambient, Marcab Regeneration is complete, and the purifier may be returned to service.

|